|

As the coronavirus (COVID-19) situation continues to evolve, technology is playing a critical role in allowing for remote working.

|

|

|

|

Dear [FIRSTNAME],

We are now facing “the new normal”, a situation to which all of us must adapt, and in which the agility in change will be a key factor for future competitiveness and even more in the industrial sector. |

|

|

|

TOP STORY |

|

|

|

Current factory status intensifies digitalization need

The crisis generated by COVID-19 is having a full impact on all worldwide industrial sectors since the lockout in productive activity in the industrial sector has been very intense and the forms of work are going to change substantially. It is, therefore, now more than ever necessary a “manufacturing without defects” and more automated and digitalized, which contributes to the optimization of production processes. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Hitachi, Microsoft to advance digital solutions across South East Asia

Hitachi and Microsoft announced a multiyear strategic alliance to accelerate the digital transformation of the manufacturing and logistics industries across South East Asia. The first solutions will be available in Thailand in July 2020. The companies will work together to meet the growing demand for predictive maintenance and process automation in remote areas and support enterprises as they tackle the challenges infused by the COVID-19 pandemic.

More...

|

|

|

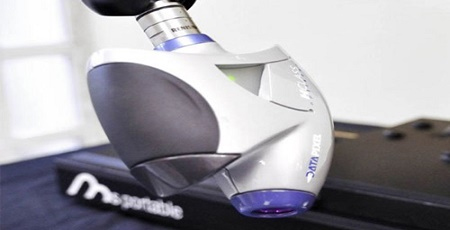

Digital solution ensures effective plant control

The Frigel Group has brought many innovative developments to its process cooling solutions for the plastics industry. Its entire product lines now include a full digital control technology plus many upgrades in almost all of its product categories. In an interview, COO Mr. Emanuele Barbagl provides an update on Frigel’s recent product developments and how these benefit plastics processors in these challenging times.

More...

|

|

|

|

|

Panasonic Smart Factory Solutions: 3D manufacturing

Panasonic Smart Factory Solutions Co., Ltd., hereinafter referred to as Panasonic Smart Factory Solutions, caters to electronic component mounting and welding machines for various manufacturers including those in the automotive industry and has established the reputation of its integrated production system by utilising its group capability. More...

|

|

|

Universal Robots now connects with industry standard protocol

The market leading producer of collaborative robots, Universal Robots, is now supporting the OPC UA standard to their robots. Norwegian software company Rocketfarm has developed the application that enables UR robots to support OPC UA. Available through the developer network UR+. The OPC UA protocol is one of the fastest growing standards for machine to machine communication and is a key component in “Industry 4.0“.

More...

|

|

|

Visionary robot feeding system

Theegarten-Pactec makes packaging even more flexible, slimmer and cost effective with its Vision Picker. With the Vision Picker, there is no need for elaborate counter-form handling during the packaging process. Using an integrated image processing system, individual products are now detected within the disordered product flow. Each product is individually sucked in by the robot and placed in the correct position in the infeed chain. More...

|

|

|

The growing potential of 3D food printing

The global market for 3D food printing was valued at $423 million in 2019 and is projected to reach a market value of $1 billion by 2025, growing at a CAGR of 16.1% during the forecast period (2020-2025), 3D Food Printing. 3D printing of food is still in the beginning stages (it is still out of reach to print cooked or baked foods, for example—an oven is still needed for now). The potential is there, proven out in the projected growth rates. More...

|

|

|

|

|

|

|

|

|

|